Table of Contents

The boundless variety of textiles can turn any clothes shopping experience from pleasant to mind-boggling. How do you know what’s better satin or silk? Are linens really made of linen? What’s the difference between chiffon and crepe-de-chine? Knowing all this is vitally important to be happy with our clothes. After all, we are in contact fabrics with all our senses on a daily basis. Knowing your fabrics is practically impossible without understanding some basic concepts of textiles, such as fabric content and construction. This post is about three main types of woven fabric.

Why is it Important to Know the Types of Woven Fabric?

Although this article gets a little technical, it is not necessarily for textile professionals. Of course, textile professionals are more than welcome to read it. To rephrase it, this post is for everyone who wears clothes during the day, uses sheets for bedding at night, and cares about comfort. In other words, this post is for everyone.

Why do you need to know the basic types of weave?

- Have you ever wondered what is the difference between satin and silk fabric?

- Does it bother you when the clothes you are wearing are itchy, clingy, staticky, and overall uncomfortable?

- Have you ever come from work and the first thing you want to do is to strip off all your clothes and change into a comfy set of peejays, sweats, or shorts?

- When you shop for clothes, do you want to know how the garment will look and feel when you wear it?

- Do you sleep better at night when your sheets are comfortable?

If you answered “yes” to any of these questions, this article is for you.

Our human body is in contact with fabrics all day and all night. And it is clearly important to know what you are wearing and what kind of bedding you sleep on.

Have you Ever Made a Shopping Mistake? I have.

No one is immune from making a shopping mistake. I am not an exception. Once, I was shopping for silk sheets. I really like silk bedding. I ordered a set of what I was led to believe were “silk sheets” from a reputable source. So I made my bed with the new sheets and lay down hoping for the divine luxury of silk. But instead, a sensation of a plastic garbage bag enveloped my entire body. The static build-up by this material was so intense, that it felt like a million tiny bugs crawling all over my body. The sheets made me very hot and uncomfortable. I could not last more than five minutes in bed which felt like a warm puddle of crude oil. So, that was the end of that purchase.

As I mentioned, I was shopping with a reputable seller. In addition, I was a satisfied returning customer in long standing with that particular business. How did I fall for such misinformation? Even popular and established sellers can hide misleading information in the product description intentionally or not.

Furthermore, the task of deciphering confusing and ambiguous product descriptions becomes even more difficult when sifting through confusing textile-related terminology. The goal I set in this post is to shed some lite on the very basic concepts of the fabric types and descriptions.

The first step in the venture to the exciting world of fabrics starts with learning some basic key concepts. When you know these simple facts, you won’t ask, “What’s the difference between satin and silk?” or “What’s the difference between wool and twill?” Reading and understanding product descriptions will become much easier. And you will be more keen on finding faulty claims and avoiding shopping mistakes.

Fundamental Fabric Concepts on the Palm of Your Hand

First and foremost, all fabrics have two essential components: content and construction.

Content means the material used to make fabrics. These materials include natural and synthetic fibers. We all know natural fibers such as cotton, wool, linen, and silk. On the other hand, synthetic fibers include polyester, acrylic, spandex, etc.

In addition, content often includes different blends. For example, common blends include cotton and polyester. Activewear often has spandex for elasticity. Synthetic materials contribute to bright colors, durability, better drape, and elasticity, but they are very uncomfortable on the skin.

You can find the classification of natural and synthetic fibers in this post.

Construction or fabric structure, on the other hand, determines how textile manufacturers assemble the fibers to produce a flat piece of fabric. We know the three types of fabric construction. They include woven fabrics, knit fabrics, and nonwoven fabrics.

For example, satin is the weave structure, but silk is the fiber that constitutes the fabric component. Hence, we should never compare satin with silk. They are two different things. You can have a silk satin shirt, cotton satin sheets, or a wool satin jacket. Combinations of various yarns or blends are very common. They are, however, different from fabric construction.

Not surprisingly, the most common source of confusion stems from erroneous comparisons of fabric structure with fabric content.

Construction (fabric structure)

| Woven | Knit | Non-woven |

| Plain Twill Satin | Warp Knit Weft Knit (described in a separate post | Felt Suede Leather |

Component (fibers)

| Natural | Synthetic |

This post is about the types of woven fabric only. I will describe knits and non-woven fabrics in separate posts.

Three Basic Weave Structures

All woven fabrics are classified into three main types: plain, twill, and satin.

Plain Weave

What is Plain Weave?

Plain weave also known as tabby weave is the simplest weave construction where one or more weft yarns alternate over and under the same number of warp yarns. In plain weave, the warp and weft yarns interlace with each other at right angles forming a square pattern. It is the most common and basic type of weave.

Pros and Cons of Plain Weave

Plain weave creates fabric with the highest durability in comparison with twill and satin weave. Needless to say, when we compare woven structures we assume that the same or similar fibers constitute the fabrics. We should not compare plainly woven gauze cotton with satin made with Kevlar fibers.

In addition to high durability, plain weave allows to achieve the highest density. It is the most efficient fabric structure in textile production. Plain or tabby woven fabrics do not unravel easily. They don’t stretch well along their grainlines. Plain-weave fabrics have their pros and cons. They wrinkle more easily, don’t have a good drape, and lack the good wicking qualities of the other two types of woven fabric.

Characteristics of Plain-Weave Fabrics

- Plain weave is the most common and simple type of weave.

- Plain weave brings about a great variety of fabrics. Examples include calico cotton, quilting fabric, poplin, broadcloth, batiste, cheesecloth, gauze, cretonne, gingham, percale, muslin, voile, and taffeta.

- Plain weave affords the most efficient usage of yarn. It is inexpensive to produce because of its simplicity.

- Plain weave is easy to produce. It is inexpensive offering maximum yardage and density at a lower cost. The yarn count determines the fabric’s durability.

- Plain weave has the highest durability in comparison with the other types of woven fabric made with the same fibers.

- Plain-woven fabrics are resistant to tear and wear. They don’t unravel easily.

- The weave structure is flat and tight.

- The appearance of a plain weave is flat and without any distinct design unless the warp and weft yarns are different in composition, color, thickness, twist, or texture. Plain-woven fabrics without print or special surface finish have no right or wrong sides.

- Plain weave is amenable for printing.

- Plain-weave fabrics are easy to handle in sewing. They also keep their shape very well in garments.

- Plain-weave fabrics do not have a good drape. They work well for adding volume to skirts.

- Plain-weave fabrics have low elasticity. They hide imperfections very well.

- They wrinkle easily.

Textile manufacturers use all fiber types in plain-woven fabrics including silk, wool, cotton, linen, and synthetics.

Variations of Plain Weave

The two variants of plain or tabby weave include balanced weave and rib weave (or unbalanced weave).

Balanced Weave

Balanced weave is a type of plain weave that has equal spacing between warp and weft fibers. These fibers are identical or similar in thickness, twist, and physical properties. Balanced weave produces perfect squares of interlacing fibers.

The thread count of balanced weave is the same along the warp and weft yarns. In other words, the number of warp threads per inch, called ends per inch (EPI) or sett, is the same as the number of weft threads per inch, called picks per inch (PPI).

A variation of balanced weave is a basket weave (aka basketweave or hopsak weave).

In basket weave two or more weft yarns float over and under the same number of identical warp yarns creating a balanced basket-like structure. A basket weave creates a checkerboard pattern. Contrasting colors in warp and weft yarns can further accentuate this checkerboard esthetic.

When the number of simultaneous warp and weft threads increases, the fabric becomes less durable because the gaps between the yarns become larger. This also creates more rubbing and faster wearing of threads. Basket weave, however, is still very durable.

Because of the larger gaps, the basket weave is quite breathable and absorbent. But it shows dirt more easily because it has an open structure.

Typical basket weave fabrics are taffeta and dimity.

Unlike balanced weave, the unbalanced plain weave has a ribbed texture. That’s why we also call it a rib weave.

Rib Weave

In rib weave, the warp and weft yarns have various thicknesses and numbers. This variation of the plain weave creates a corded texture.

Poplin is an example of a rib weave where heavier weft yarn intertwines with a greater number of finer warp yarns.

This type of weave has a distinct rib-like structure. These yarns can substitute each other in a warp or weft direction.

Rib weave offers a very good drape. Its prominent ribs affect the durability of the fabric. Tension may cause yarn slippage.

Typical Fabrics Made with Plain Weave

- Bengaline is a fabric with a fine crosswise plain rib weave using rayon, nylon, polyester, cotton, or wool often in combination. Originally, Bengaline was a type of faille dress fabric that replaced silk with cotton as its main fiber.

- Chiffon is a very light, sheer fabric made with crepe yarns.

- Dimity is a lightweight cotton fabric in a 2:2 basket weave.

- Dupioni (also referred to as douppioni, doupioni, or dupion) is a plain-weave silk fabric with a shiny surface and a crisp handle. Dupioni has fine yarn in the warp and slub yarn reeled from two or more entangled cocoons in the weft (filling). It is thicker and more coarse than shantung.

- Faille is a dense fabric with prominent weft ribs. Originally, Flemish women used silk faille for their head coverings. Modern faille manufacturers use other natural and synthetic fibers.

- Grosgrain is a heavy fabric with a distinct rib weave. Silk or rayon are the typical fibers in grosgrain. But you can easily encounter synthetic grosgrain material.

- Habotai is a lightweight and soft fabric. Silk Habotai was a traditional material for kimonos.

- Organza is a thin, plain weave, sheer fabric with very low density.

- Poplin is a thin and densely woven fabric with a smooth and lustrous surface. Originally, cotton poplin was the common fabric in formal wear.

- Rep (also known as rip, repp, or reps) is a rib-woven fabric with fine cords in the filling (weft). Traditionally, the constituent fibers of rep are silk, wool, or cotton. Nowadays, however, rep is commonly a synthetic material.

- Shantung is a type of plain-weave tussore silk fabric with ribbed irregular texture. Shantung may have slubs. It is similar to dupioni, but is slightly thinner and less irregular.

- Taffeta is a lightweight fabric made with yarn that is twisted while it is woven.

Twill Weave

The other two basic types of weave, twill and satin use floats.

A float is a segment of warp or weft yarn that extends over two or more counterpart yarns without interlacing them.

Perhaps, the most versatile and popular type of weave in home and clothing textiles is twill. Because of their durability, drapeability, resilience, resistance to stains, and visual appeal, twill fabrics have a considerable number of uses from interior and auto upholstery to bags, coats, jeans, chinos, shirts, bedding, lining for garments, and more.

What is Twill Fabric?

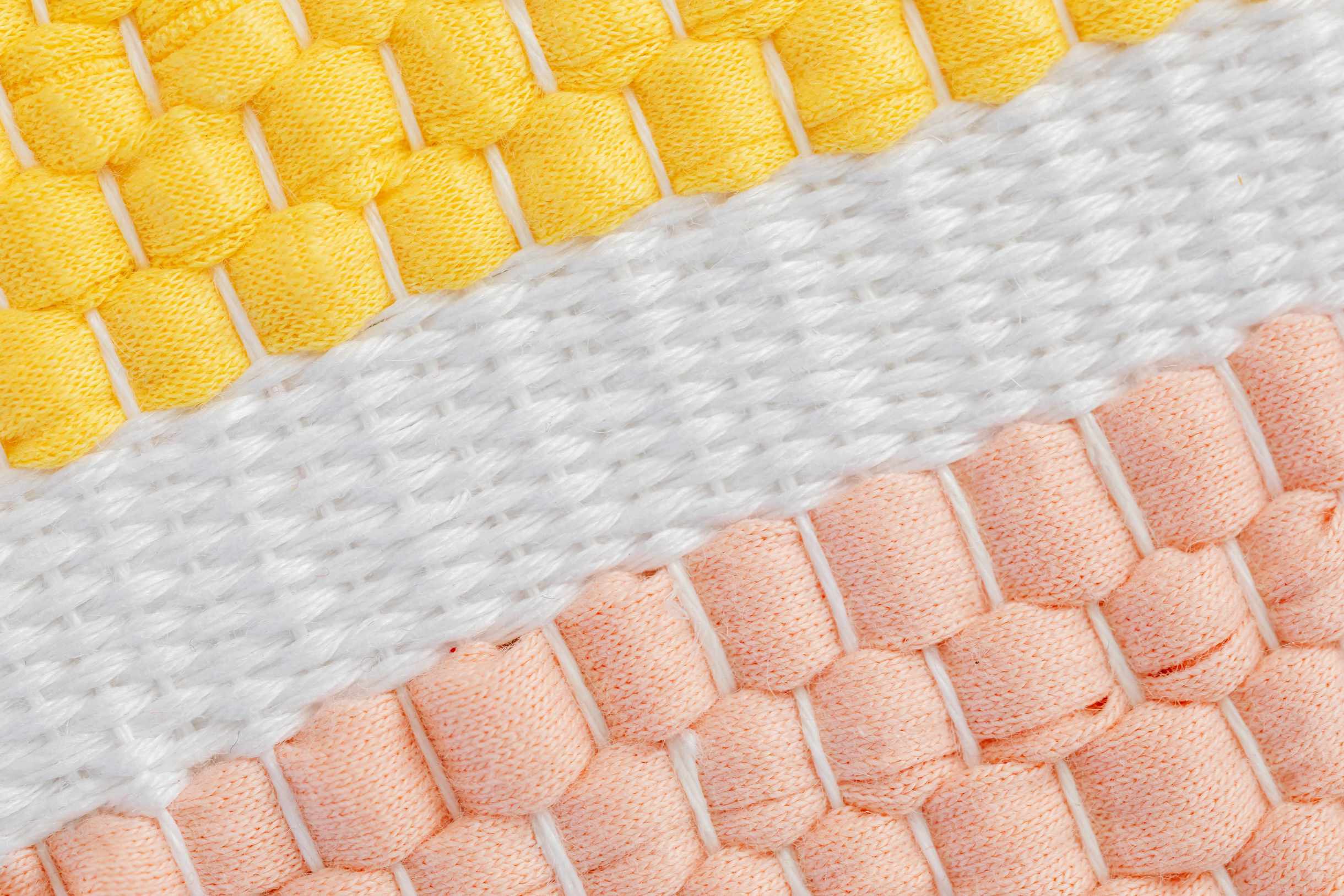

Twill Weave Structure

Twill weave is created by two or more warp or weft floats repeated with an offset in a diagonal fashion.

Let’s see how it’s done.

In the first row, a weft thread floats over one or more warp threads and then under one or more warp threads. In the second row, the pattern repeats, but with an offset also known as step. This pattern repeats with such a step (offset) in each progressive row creating a diagonal pattern of parallel ribs also called ridges or wales.

Classifying Twill

We use fractions to classify twill fabric. These fractions describe how the yarns intertwine. For example, a 4/1 twill means that the weft yarn floats over three warp yarns and under one warp yarn as shown in the diagram. The total of four warp yarns in a pattern requires four harnesses (shafts) on the loom.

Characteristics of Twill Fabric

Twill Appearance

Twill Textures

When you look at the twill up close, you notice a pattern of parallel diagonal ribs. This diagonal texture can run in the right or left direction depending on the arrangement of steps. The diagonal directions can change on the loom to achieve variations of twill weave. The most common varieties of twill designs are tartan, herringbone, chevron, houndstooth, and corkscrew. Because of the high thread count twill weave is typically thick and opaque. Twill appearance ranges from muted to shiny.

Colors and Patterns of Twill

Twill fabrics usually don’t have printed patterns. Instead, different colors of warp and weft yarns create a great variety of geometric designs.

Denim is a good example of twill interlacing indigo and white yarns giving it the characteristic speckled look. In addition, denim is a very strong and durable fabric. Blue denim, for instance, has a white warp and indigo weft forming diagonal blue wales on white background.

Twill garments made of wool in tweed or plaid patterns became signature styles in Scottish and Irish fashion.

Physical Properties of Twill Fabric

Twill weave creates greater drapeability and resilience than plain weave with a considerable variety of designs. Drapeability is the ability of a fabric to float smoothly as it hangs. Fabrics with a low drape are crisp and rigid. But high-drape fabrics are smooth, supple, and fluid in appearance and feel. Resilience is the ability of a fabric to return to its original shape after stretching.

- Twill has a high thread count making it strong, thick, and hardwearing. It is long-lasting and resistant to tears.

- Twill weave gives fabrics an excellent drape and resilience.

- This combination of high durability and drape gives twill popularity for upholstery, work and recreational clothing, bath towels, and bed linens.

- Twill weave creates a ribbed diagonal pattern whose combinations yield a wide variety of textured geometric designs.

- Twill is thick and opaque. It is suitable for formal men’s clothing, drapes, and outerwear.

- Twill is resistant to stains because of the fabric’s thickness and textured pattern.

- Twill weave is wrinkle-resistant.

Uses of Twill-Weave Fabrics

The beneficial properties and distinct appearance of twill make it a very popular weave.

- Work clothes and uniforms. Denim cotton jeans and jackets as well as heavy overalls, coveralls, and painter pants made with drill or denim are the staples of workwear and recreational clothing.

- Formal clothing. Twill weave is very popular for tuxedos and formal suits.

- Business casual attire. Chino cotton, for example, is common for slacks, Dockers, and other relaxed-fit pants.

- Hiking, hunting, recreational apparel, tents, backpacks. Because of their durability, comfort, and low noise on rubbing, twill fabrics are popular for nature sportswear, backpacks, and tents.

- Coats and jackets. Tweed, herringbone, chevron, and houndstooth twill designs are common in warm and heavy wool coats, jackets, suits, scarves, etc.

- Linens and towels. Soft and absorbent twill pile fabrics are perfect for towels and bathrobes. Flat twill, on the other hand, is a typical weave for bed linens, throws, and shams.

- Drapes and upholstery. Because of their thickness, high density, and opacity, twill fabrics are popular for window treatments and soft furnishings.

Typical Twill Fabrics

Traditionally, twill was made with natural fibers such as wool or cotton. But nowadays, twill fabrics are synthetics for the most part. Below is a list of twill fabrics with their original yarn content.

- Bedford cord can be plain or twill (drill) weave. Similar to corduroy. (Cotton).

- Chino (cotton, linen)

- Corduroy (cotton)

- Covert (wool)

- Denim (cotton)

- Drill (unbleached heavy-weight cotton or linen)

- Flannel (brushed cotton or wool twill fabric)

- Foulard (lightweight fabric, either twill or plain-woven, made of silk or a mix of silk and cotton)

- Gabardine (silk, wool, or blends)

- Surah (silk)

- Serge (2/2 weave with diagonal ribs on the right and wrong sides)

- Wool serge is the fabric of military uniforms, suits, trench coats

- Silk serge is used as lining fabric

- Tweed (wool)

Satin Weave

The last, but not the least of three main types of weave is satin. Fabrics created with satin weave are very soft, smooth, and shiny. These fabrics are very comfortable, elastic, and pliable creating well-fitting and elegant outfits with graceful drape. Satin linens and upholstery are shiny and luxurious. No wonder, satin is the exclusive upholstery fabric in all furniture of Versailles!

What is Satin Weave?

Just like twill, satin fabric is woven on a loom that has multiple harnesses (or shafts). However, a satin loom uses four to twelve harnesses, which is even more than a twill loom.

In satin weave, a weft yarn floats over three or more warp yarns, then under one warp yarn. Alternatively, satin can have three or more warp over weft floats followed by one warp under weft.

The rows woven with an offset of one step give satin an uninterrupted diagonal pattern. This diagonal pattern is almost indiscernible.

The long floats determine the luster and elasticity of satin fabric. The longer the float the shinier and more stretchy the fabric. Satin fabric is reversible. The front is shiny and the back is very dull due to the arrangement of warp and weft yarns.

Variations of Satin Weave

Satin can be classified based on the length of the warp or weft floats described by ratios. The ratios range from 4/1 to 12/1. The first number refers to the number of harnesses (shafts) on a loom and determines the repeating pattern of the weave. For example:

- Four-harness satin (4/1 weave). The loom that creates this weave has four harnesses or shafts. In a 4/1 satin weave, the weft yarn floats over three and under one warp yarn. This type of woven fabric gives more elasticity and shine to fabric compared to plain or twill weaves.

- Five-harness satin (5/1 weave). This weave uses five shafts (harnesses). The thread pattern is made by floating weft yarn over four and under one warp yarn. This list goes all the way to a 12/1 ratio.

- Twelve-harness satin (12/1 weave). A loom for this pattern has as many as 12 shafts. The weft yarn floats over 11 warp yarns and then under one warp yarn. This satin variant gives the most sheen and elasticity to fabric.

What is the Fiber Content of Satin Fabric?

The long floats of satin require special threads. They have to be durable enough to resist wear and tear. Filament yarn instead of staple yarn is the perfect fiber for satin type of woven textile. Filament yarn is a long continuous fiber. Staple yarn is created by spinning relatively short fibers into a long yarn. Wool and cotton are staple yarns. But the natural filament yarn is silk. Silk fibers are extremely long filaments.

Historically, silk was the only fiber for satin that came about on the brink of the 12th century in China. Maybe this is the reason for the widespread confusion between silk and satin.

The other natural fiber used to make satin is linen. Although, linen is a staple yarn the linen staples are very long rendering it appropriate for a traditional satin weave.

Short staples can unwind in satin floats caused by movement and rubbing of fabric when in use. That is why only long filament yarns are appropriate for satin. Although wool is a staple yarn, fine wool is suitable for satin weave because wool tends to become stronger during wear.

While silk is the most traditional fiber of satin, silk is becoming less and less common. Synthetic filaments such as polyester, nylon, rayon, or modal are more common materials in satin fabric nowadays. When you are shopping for satin garments, sheets, or fabrics, beware of the abundance of petroleum-based synthetics such as polyester, nylon, or spandex.

In our store, however, you will find only natural silk satin.

Characteristics of Satin Weave Fabrics

Satin fabric is extremely lustrous, with remarkable drapeability. It complements the figure beautifully. That’s why satin is very common in feminine attire and nightgowns. Satin is quite delicate. Because of the uninterrupted diagonals, they can snag easily.

Satin fabric is shiny and luxurious. A silk satin garment feels like a luxurious and soft caressing cloud.

- Satin is a fine fabric that is smooth and compact in appearance with a bright luster.

- Satin has a flat and tight weave structure. Satin is usually made with very fine fibers giving it a high thread count.

- The continuous warp diagonals are visible under a magnifying glass.

- Satin has remarkable drapeability. It is a very soft and pliable fabric that molds to shapes, accentuates, and complements the figure.

- Satin has two sides: a shiny front and a dull reverse side.

- Satin is wrinkle-resistant. Similar to twill, satin wrinkles much less than plain-woven fabrics.

- Satin is not as durable as the other weaves. The longer the floats, the less durable the fabric is.

- If you make garments, curtains, or linens yourself, you know that satin is difficult to work with. It floats on the table and lining up pattern pieces takes time. One solution that I use is to spray your satin fabric with a fine mist of water, it becomes much more manageable. But be careful not to stain the fabric.

Uses of Satin

Because of the luster, softness, and excellent drape, this delicate fabric is best for feminine attire, nightgowns, lingerie, linens, curtains, and drapes. Here is the short list of satin uses:

- Evening gowns

- Wedding dresses

- Shirts and tunics

- Lingerie

- Clothes liners

- Bedding

- Curtains and Drapes

- Upholstery

- Footwear: ballet slippers, designer shoes

- Belts

- Evening purses and bags

Typical Satin Fabrics

- Antique satin or satin-back shantung is woven on a 5- or 8-harness (shaft) loom using slub yarns (unevenly-spun novelty yarns) in the weft (filling).

- Baronet has a cotton back and a rayon or silk front, similar to Georgette.

- Charmeuse is a lightweight fabric in which the warp threads cross over four or more weft threads. Charmeuse is glossy in front and dull on reverse. Charmeuse may be made of silk, polyester, rayon, or blended yarns.

- Crepe-back satin has a glossy satin front and a crepe texture in the back. Crepe-back satin is most commonly made of polyester and sold as make-believe silk. The real silk crepe-back satin fabric is very luxurious.

- Duchesse is an 8- to 12-harness satin weave with closely positioned warp yarns. Duchesse is a dense fabric with a high thread count. Originally, Duchesse was made in France from silk, but it is increasingly made with synthetic fibers.

- Sateen is a satin fabric that is woven with staple yarn such as cotton, wool, or linen instead of filament yarn. By definition, sateen cannot be made of silk or polyester as they are filament fibers.

- Slipper satin is a strong medium-weight satin with a high luster used for women’s footwear, ballet slippers, garments, and accessories.

The three fundamental weaves are used for all intents and purposes. I hope that after reading this post, you are better equipped to shop for your clothing, drapery, linens, and upholstery to fit your personal needs.